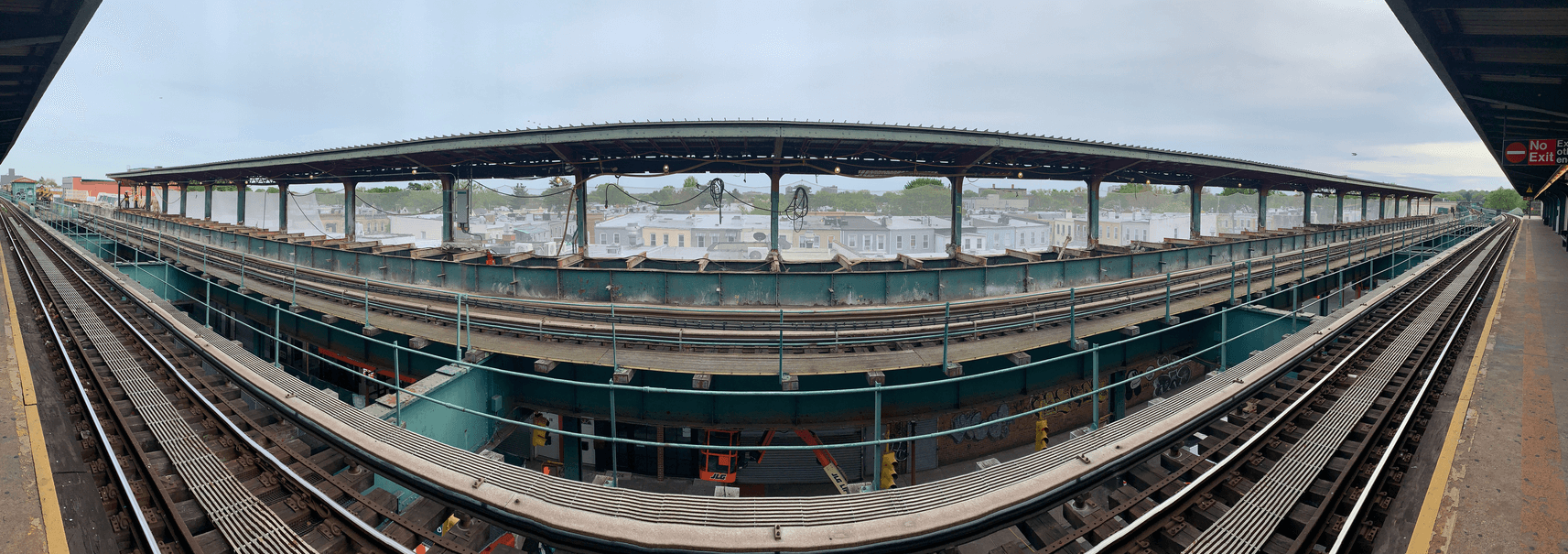

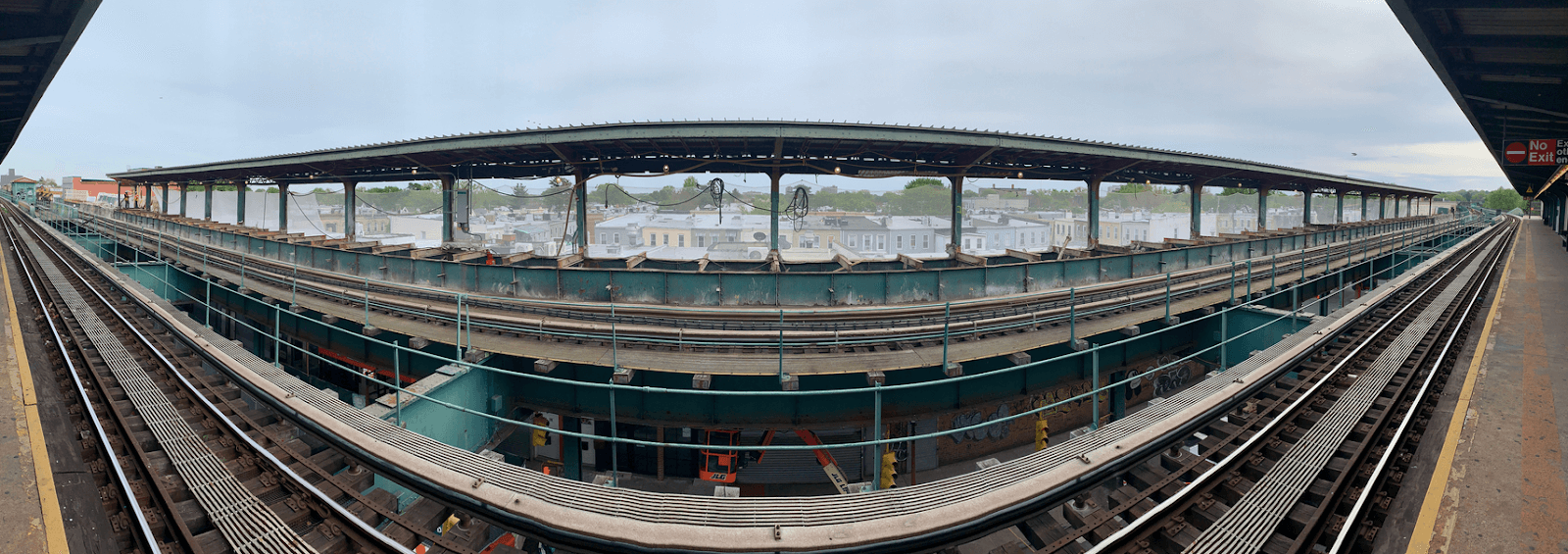

Gramercy Group is proud to lead the repairs of three MTA stations along the Jamaica “J” Line. One of the stations being restored is the elevated train platform at the 75th Street-Elderts Lane Station in Woodhaven, Queens, New York City. Here, Gramercy needed to complete the demolition portion of the project in just two days. The entire project is a joint venture with Paul J. Scariano, Inc. and also includes steel contributions by Northeast Structural Steel.

Gramercy Group Demolishes the Old 75th Street – Elderts Lane Station Platform

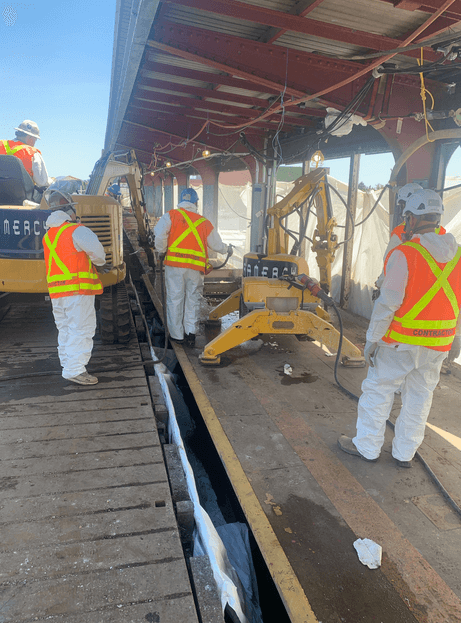

For the demolition portion of the project, Gramercy was able to utilize the train tracks and a diesel car to bring in equipment to the elevated tracks. Brokk demolition robots were brought in to break down the concrete platform. Operators had only two days, Saturday and Sunday, during daylight hours to demo approximately 4,800 sq ft of concrete platform. To accomplish this amount of demolition in two 12-hour shifts was unprecedented for the MTA.

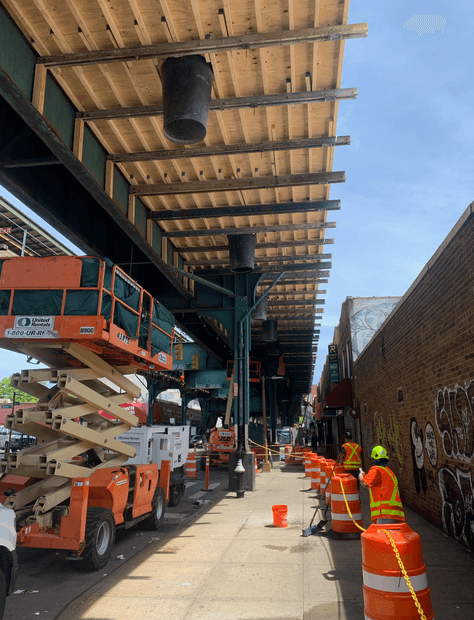

Work Platform and Debris Chutes Provided Safety and Efficiency During Demolition

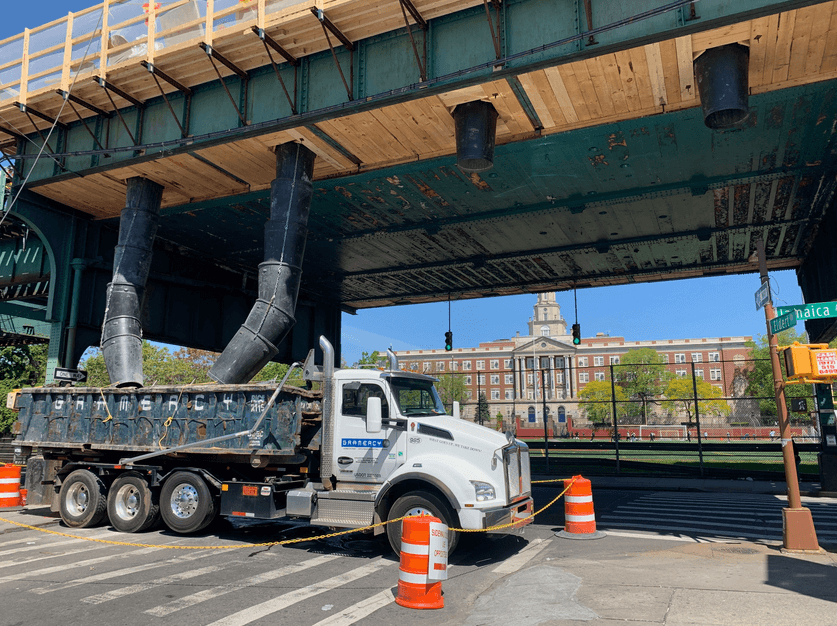

Since this project involved demolitioning concrete on an elevated train track, safety was a major priority. Before any demo work began, a working deck and debris shield needed to be constructed to not only prevent any debris from falling, but also provide a pathway for workers and a streamlined disposal system for efficient removal of rubble. Chutes were installed within the work deck to quickly remove debris by way of dumpsters, which could be loaded and driven away.

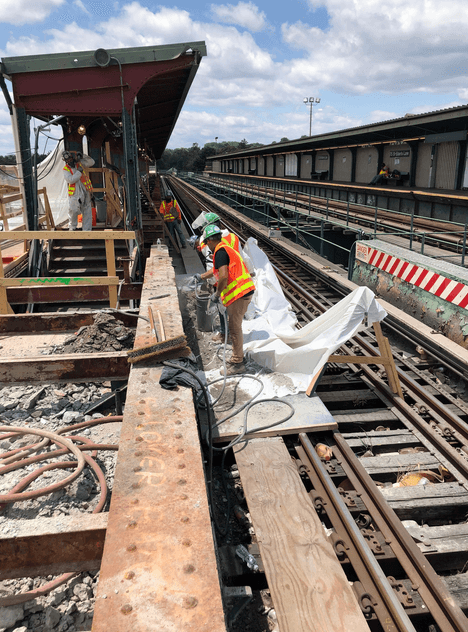

Even though the focus was on demolishing the platform slab, some of the concrete from the old platform required hand demolition of the through spans at track level. This meant the teams had to work directly on the tracks, so service was shut down during the least disruptive time, and a general order was issued for weekends.

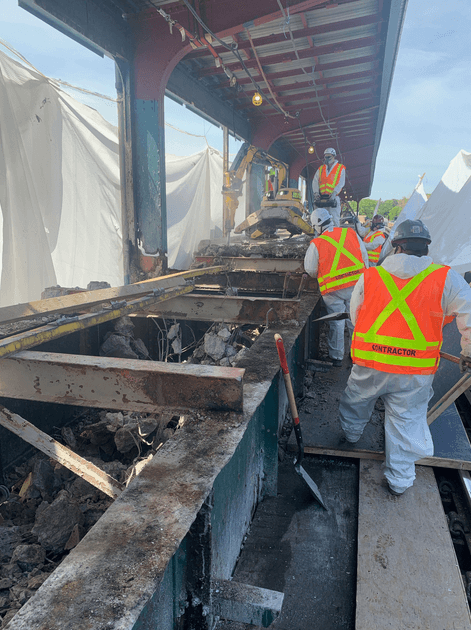

The process began with the demolition of the previous concrete platform.

As apparent from the existing steel under the platform, this project was desperately needed to ensure the safety and integrity of the platform structure as the steel was worn and eroding.

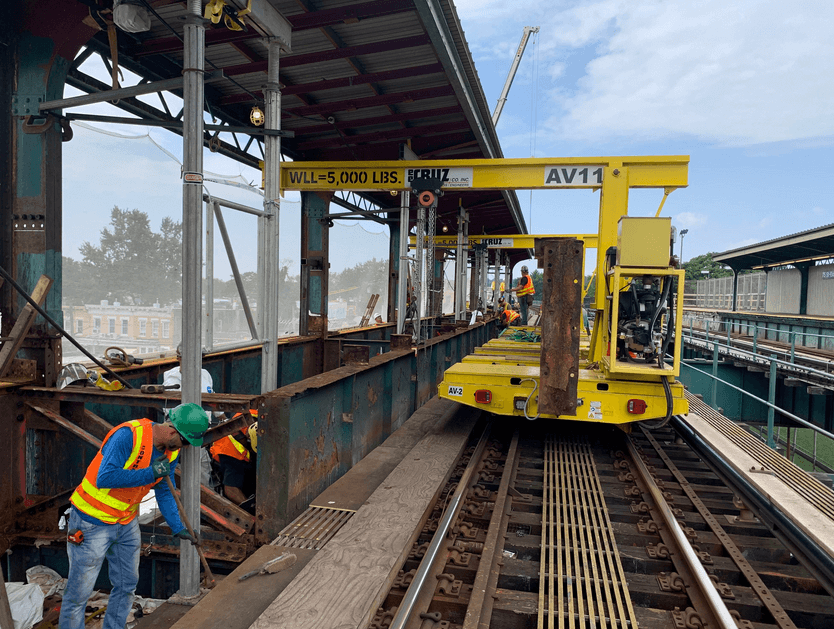

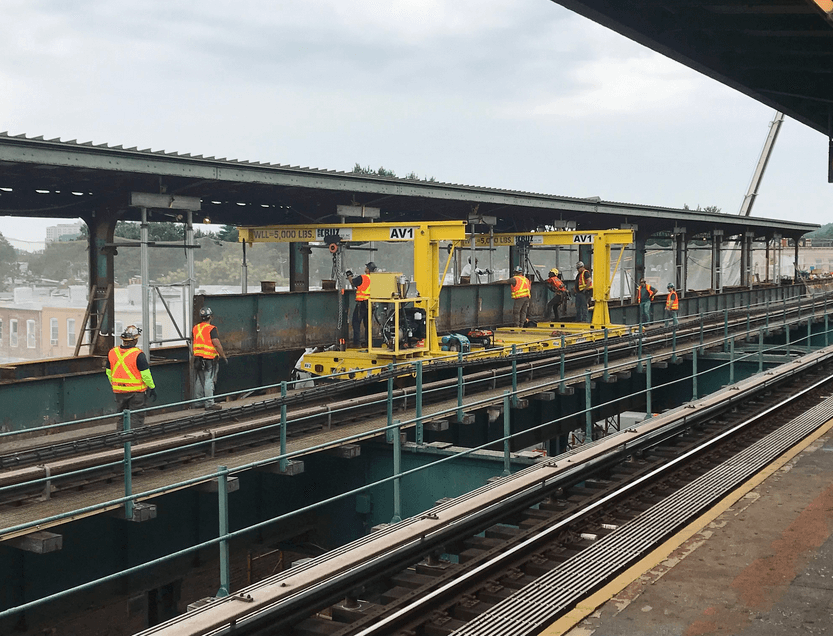

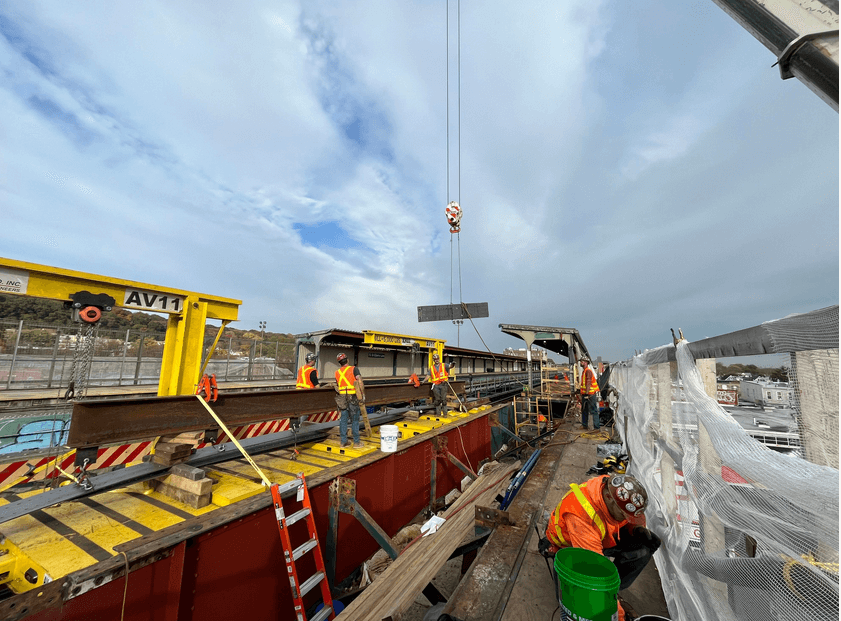

A Gantry System Was Essential for Assisting with the Removal and Installation of Platform Girders

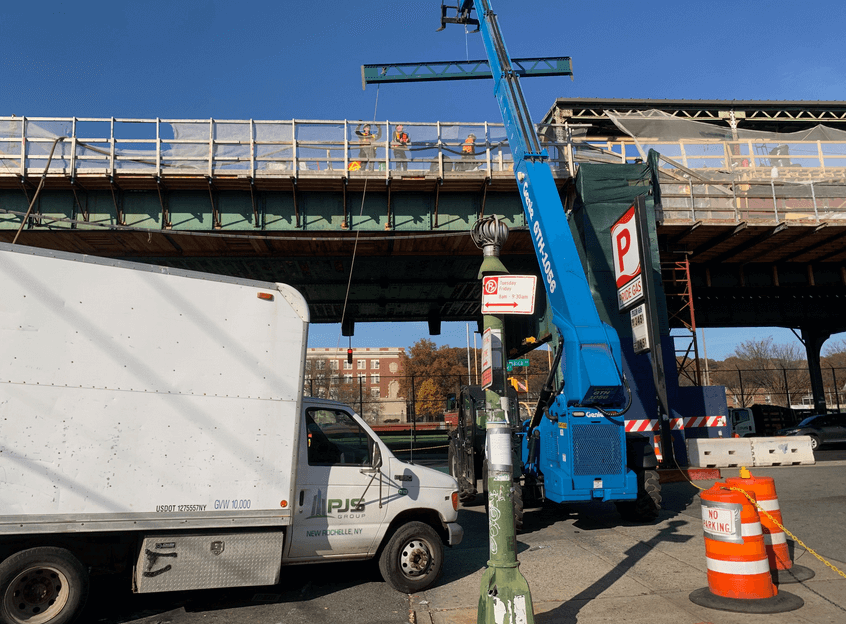

Northeast Structural Steel used a gantry system, which needed to be elevated with a crane to place it on the tracks and, once in place, removed and reinstalled the platform girders.

While the gantry moved up and down the tracks assisting with removing and installing new girders, a crane was necessary for bringing new pieces up to the machine and removing the old pieces from the gantry.

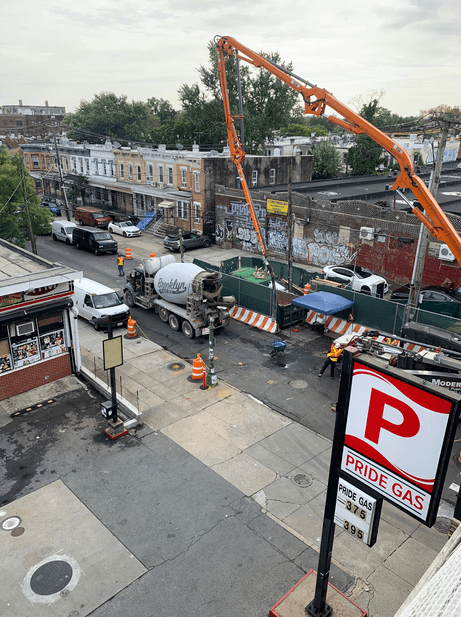

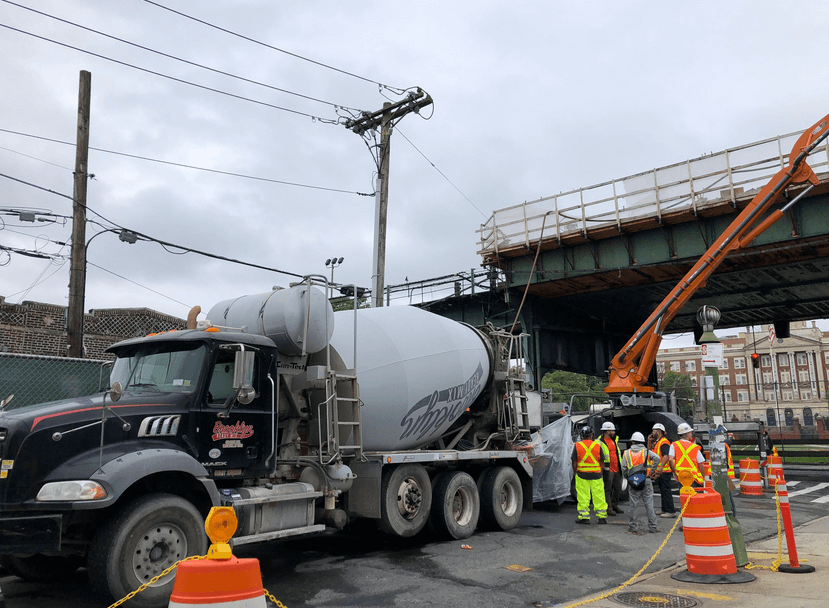

Pouring Concrete from the Ground to the Elevated Platform Required a Unique System

To create the new concrete slab on the elevated platform, the team required a pump truck to convey the concrete up to the platform area. A process was created where all of the concrete pulled up to the pump truck and the concrete mix was poured into one end of the pump truck and then dispersed out of the extended arm and through a piping system into the platform area.

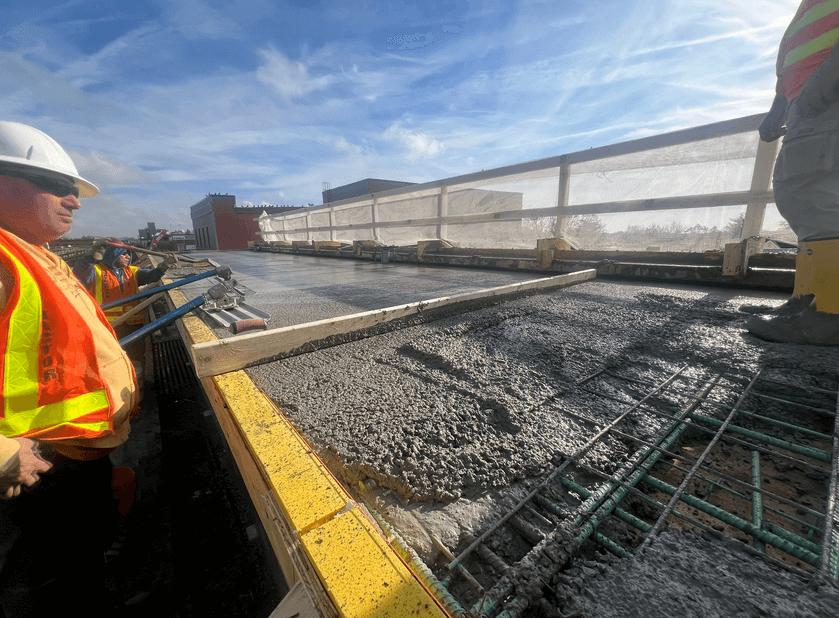

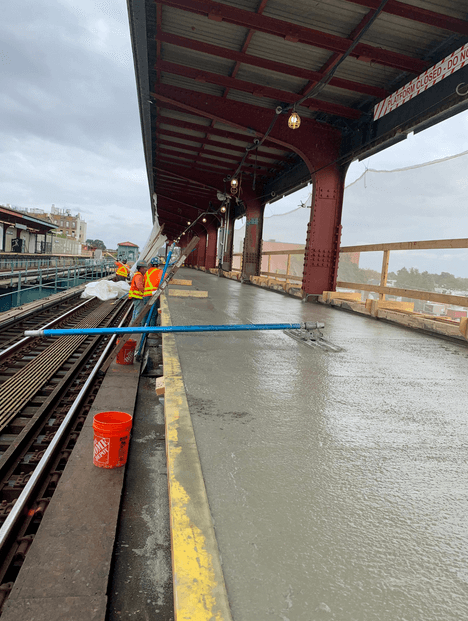

Gramercy needed to create a system for the masonry team to access the space from the front edge to the back edge. Once the concrete was poured, masons vibrated the concrete to make sure all of the sediment settled properly so that it developed the proper strength and settled properly into all of the crevices. The MTA requested a broom finish to the platform to ensure that when passengers walk on the platform surface, it is safe and not too slippery, particularly when wet. To create this texture, fine tip brushes were used to create just the slightest amount of roughness in the slabs.

Since this project was completed in the winter of 2023, the cold weather needed to be factored in. After the concrete was ready to cure, it needed to be covered while damp to allow it to properly cure at the correct temperature and prevent cracking. Heated curing blankets were used to help keep the concrete at the ideal temperature of around 50 to 60 degrees.

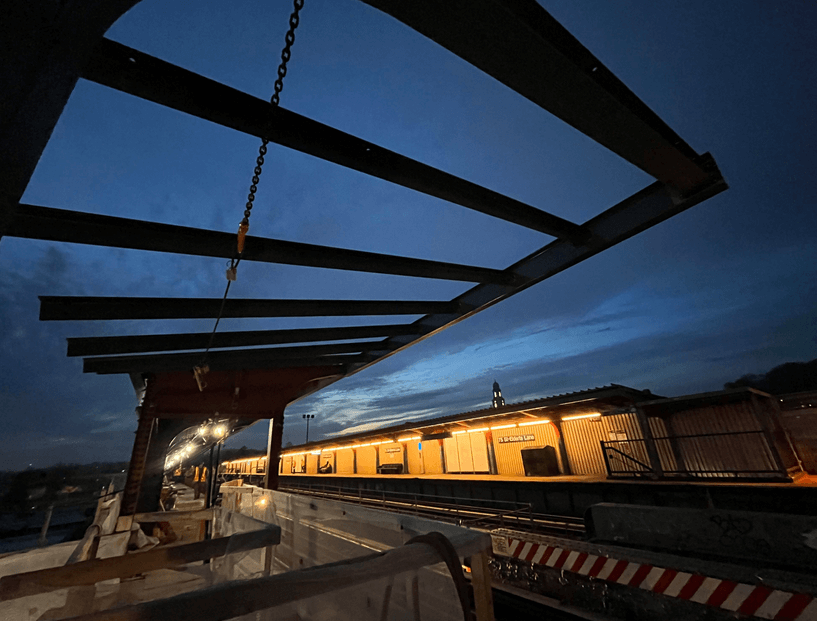

The Project Comes Together with Final Steps

In addition to the new platform, the MTA requested a canopy extension over the staircase be added to the construction project as one had not existed before. With the roof framing in place, roof panels followed,protecting passengers and the structure from the elements and the harsh weather conditions New York City often sees throughout the year.

The original girders had signal cables for the trains so once the new steel pieces were in place and painted, electricians prepared the area to attach new brackets and cables onto the girders.

Gramercy directly focused on completing the demolition, concrete and rebar with our JV partner. Beyond this, Gramercy worked closely with our steel subcontractor to manage the completion of this portion of the work. Between direct completion of work and coordination, this portion of the MTA Jamaica Line contract was a major accomplishment that involved weekend work under tight deadlines and significant coordination. Learn about our Hart Island Chimney Stack Felling and get to know some of our team with on our recent team profiles post.